Smartex sews up $24.7M to put smarter eyes on textile manufacturing • ZebethMedia

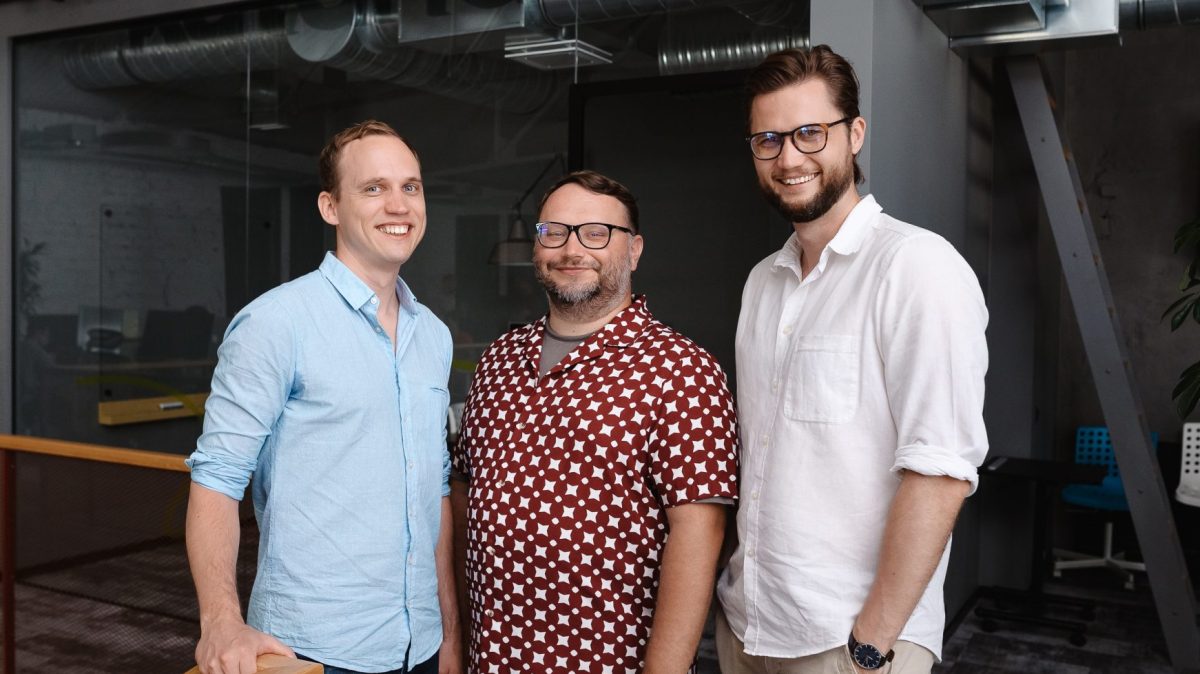

A lot of things might spring to mind when you hear “fashion,” but taking care of the planet generally isn’t on that list. Smartex just raised a couple of bolts’ worth of cash, sowing up a round of funding to bring smart tech to fabric manufacturing. The hope is to be able to detect textile defects in real time. The company is pushing hard on the green angle for its products. Smartex has developed machine-vision-driven software that makes fabric production more efficient by identifying defects, which primarily can be used to stop manufacturing if something is going wrong, preventing waste. In particular, the company argues that imperfect fabric can travel down the supply chain, with product issues only getting discovered much later in the manufacturing process. “I was born and raised by textile factory workers, I worked in factories when I was a teenager, I have a master’s in physics and the textile industry has been chasing me since ever,” said Gilberto Loureiro, co-founder and CEO of Smartex, in an interview with ZebethMedia. “We co-founded Smartex because we’re obsessed with solving problems — and the textile industry has big ones. It’s probably the industry with the worst ratio size / automation. Textile factories don’t have the tools to produce in a clean, transparent, efficient way… generating massive amounts of waste and other problems.” The company declined to share the valuation of its $24.7 million round, but told ZebethMedia it was led by Lightspeed Venture Partners and Tony Fadell’s Build Collective. Additional funds were raised from clothing giant H&M Group, DCVC, SOSV’s HAX, Spider Capital, Momenta Ventures, Bombyx Capital Partners and Fashion for Good. The company previously raised a $2.9 million seed round in 2019 co-led by DCVC and Spider Capital. Smartex’ founders, Antonio Rocha, CTO & Co-Founder, Gilberto Loureiro, CEO & Co-Founder, and Paulo Ribeiro, VP of Engineering & Co-Founder. Image Credits: Smartex. “It’s fantastic to work with such mentors that have invaluable experience. Lightspeed Ventures is a truly global firm and supports us in many geographies we operate, Paul [Murphy from Lightspeed VP] is also an operator with tremendous insights in scaling businesses,” said Loureiro, “Tony Fadell and his team are world-class mentors and operators with a unique product and marketing approach. Tony’s recent book “BUILD” is one of our bibles.” These Series A funds will enable Smartex to expand the business to new geographies and to continue to grow the team. “I’m so excited about textile production in Asia and all the mega-factories in Bangladesh, Vietnam, China, etc. No one will ever solve textile problems without having a deep understanding and presence in these markets. So, going into all the cultural aspects and making businesses here is really awesome,” said Loureiro. “Our ultimate vision and long-term goal is to expand into other industries to enable factories around the world to produce with significantly less waste. We won’t stop until we have made a massive difference.” It takes a rather sturdy stomach to take on an entrenched industry where a lot of the manufacturing facilities don’t have the necessary infrastructure to run AI-powered QA, but it’s a changing industry. “This industry is very challenging! That’s one of the reasons why few tech companies operate in here. We feel blessed to be already creating a massive impact — but when compared with the overall size of the industry, it feels like nothing,” Loureiro explains. “If there was ever a time to solve massive problems — it’s now!”